Sectors

Automotive

Productivity

400

Applied technology

Marking

Camas Technology

Rotay table, vision system and EoL test

Tests

Functional tests

Main features: rotary table with 8 dividers, semiautomatic, two pieces processed simultaneously, assembly, inspection and laser marking.

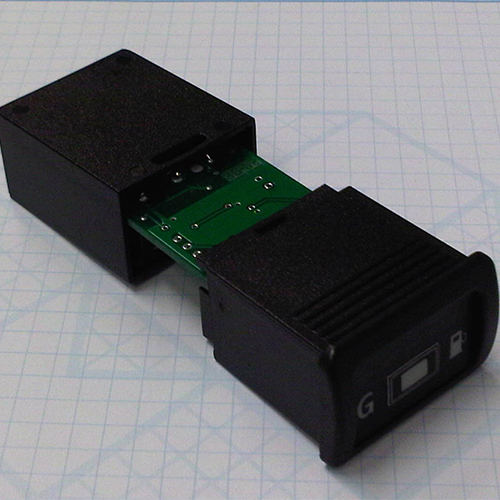

Rotary table machine with 8 stations and pneumatic power component movement. Loading carried out entirely by operator. Possibility to process diverse commutator models.

The line performs assembly and functional inspection using:

• Circuit programming equipment;

• “Light guide” inspection equipment;

• Vision system for controlling LED functioning;

• Final inspection equipment with function simulation and control of button engagement;

• Laser marking unit (in the case of specific logo and data matrix).

Saving of all production and testing data, as well as incoming Work Orders, through the interface with the external SQL server to guarantee total traceability of each single piece and remote management.