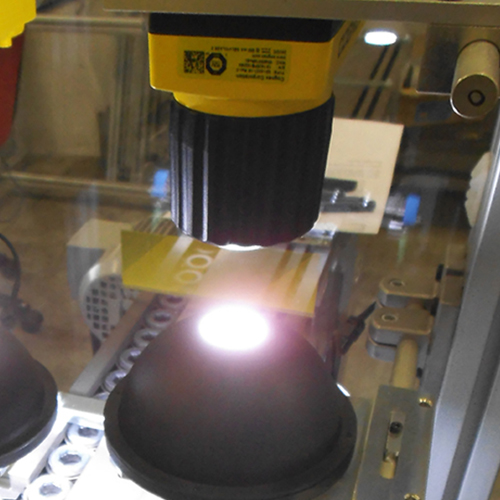

Vision systems make it possible to monitor 100% of your production accurately and efficiently, thanks to the customized selection of sensors and optics that match the precision required. Today, vision systems monitor from simple piece absence or presence to completeness, color, shape, size, and correct position. Single or multiple systems can be installed simultaneously, fixed or mounted on linear axes or end-effectors. Monitoring can be made both in 2D and 3D mode. Automatic calibration can be scheduled for consistent repeatability. Programming of the vision algorithms is accessible to operators, who can perform it completely independently. In addition to performing checks, vision systems can also be used for piece recognition, orientation, and robot guidance systems to enable to load components that prove difficult to feed or store in boxes or chests.

At Camas, our expertise allows us to build and integrate vision systems into our assembly and testing lines.