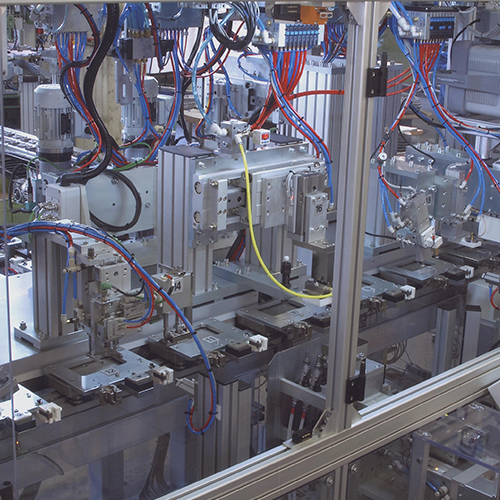

In contrast to rotary machines with rotary tables, an alternative solution is represented by a linear system with a straight layout having two variables: a free pallet system (with pallet transport conveyor) and a fixed step system (with pallet movement via a chain and brushless motor assembly).

Free pallets

In many cases, due to the flexibility required, the presence of operator stations, and the need for different cycle times from assembly to testing phases, the best solution employs linear lines. These machines have pallets that re-enter the loop and are indexed when they are processed. This approach can handle components of nearly any size, from a needle to an entire refrigerator.

In free-pallet machines it is possible to integrate any stations missing along the belt, allowing differentiating cycle times, by buffering and accumulating pallets before the stations whenever inspection and testing operations are longer than the assembly cycle.

Fixed step

While maintaining a similar layout, the main difference in a fixed-step linear system with regard to the previous system consists of a constant distance between the various pallets while maintaining constant pallet exchange below the station.

This solution using chained pallets makes the most of the characteristics of the features of the rotary table combined with flexibility in positioning the various stations, in terms of the dimensions of the stations, as well as improvement in machine accessibility.