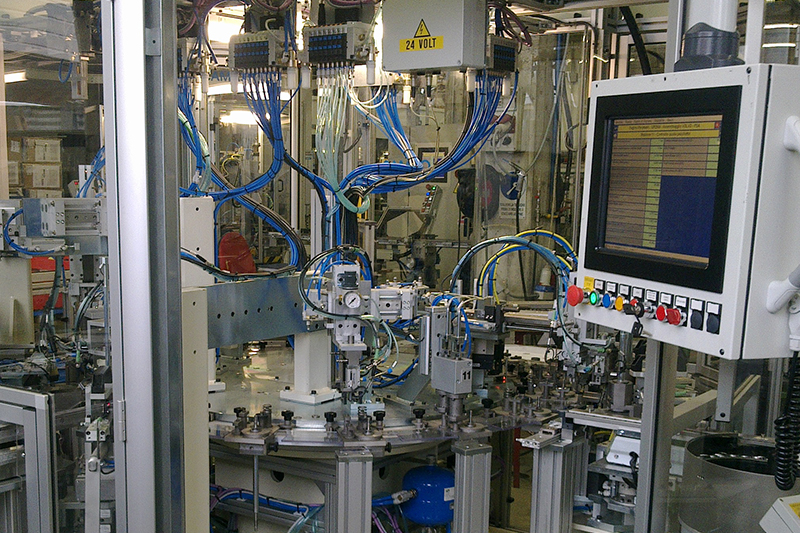

Various machine designs are based on an indexing mechanism, topped with an aluminum disk to create a rotating surface. The piece is transferred from one station to the next and is completed and inspected in sequence. This is the basic principle of rotary transfer machines.

Over the years, various mechanisms have been used, from the Geneva drive to flat indexers to barrel or globoid cams. Ring systems are also increasingly used. These allow the machine to extend out from the middle offering improved accessibility, and systems based on thrust blocks and brushless motors make it possible to have different sets of placings mounted on the machine for use in assembling different models without retooling the machine. Rotary transfer machines offer an excellent compromise between footprint, number of stations, and affordability of the solution.

The system makes it possible to bear heavy loads perpendicular to the surface and to employ circular motion to move components quickly among the various stations.

Often the indexer is not fastened to a disk, but instead to a oblong guide, making it possible to build transfer machines with a linear layout. These machines feature rapid exchange, more flexibility in terms of number of stations, and a different accessibility compared to table systems.